Produktion von Holzpaletten: Wichtige Aspekte, Technologien und Verarbeitungsprozesse

Share

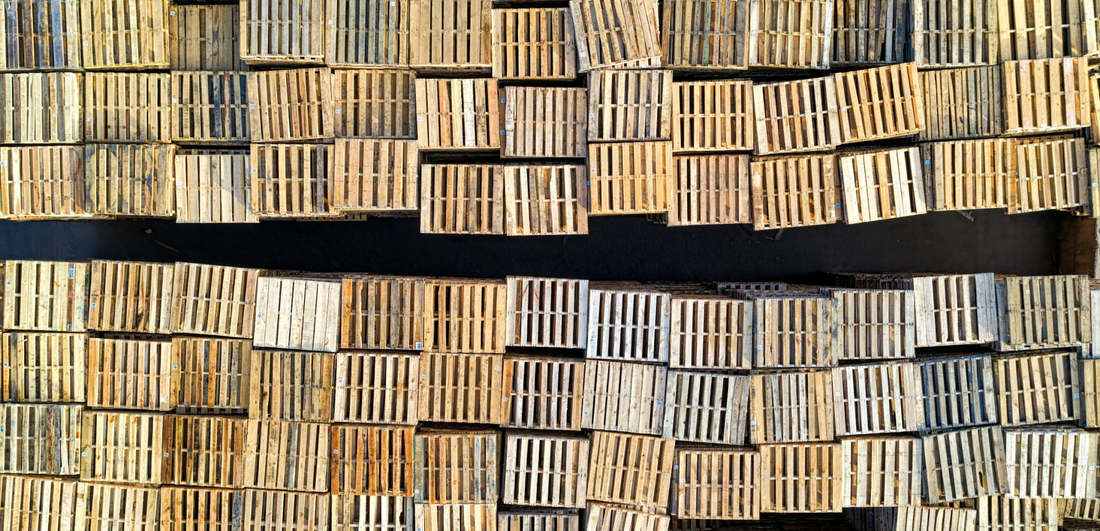

Holzpaletten sind ein unverzichtbarer Bestandteil der modernen Logistik. Ihre Produktion ist ein komplexer Prozess, der die Auswahl hochwertiger Rohstoffe, den Einsatz fortschrittlicher Technologien und eine strenge Qualitätskontrolle in jeder Phase umfasst. In diesem Artikel werfen wir einen genaueren Blick auf die wichtigsten Aspekte der Palettenproduktion, moderne Technologien, Methoden der Holzverarbeitung und deren Bedeutung für die globale Wirtschaft.

Warum ist die Produktion von Holzpaletten so wichtig?

Die Produktion von Holzpaletten bildet die Grundlage der logistischen Infrastruktur. Sie werden in allen Branchen eingesetzt, von Landwirtschaft und Lebensmittelverarbeitung bis hin zu Bauwesen und Pharmazie. Hier sind die Hauptgründe für ihre Bedeutung:

- Wirtschaftliche Vorteile: Paletten optimieren Transport und Lagerung und senken die Kosten.

- Umweltfreundlichkeit: Holz ist ein erneuerbarer Rohstoff, und Paletten lassen sich leicht reparieren und recyceln.

- Standardisierung: Internationale Standards wie EPAL und ISPM-15 gewährleisten Kompatibilität und vereinfachen logistische Prozesse.

Phasen der Holzpalettenproduktion

Die Produktion von Holzpaletten umfasst mehrere Phasen, die je nach Verwendungszweck und Produktstandards variieren können. Schauen wir uns diese genauer an:

-

Auswahl des Holzes

Die Wahl des Rohmaterials ist eine entscheidende Phase. Für Paletten werden typischerweise verwendet: - Weichhölzer: Kiefer und Fichte, die für ihre Verfügbarkeit und Leichtigkeit geschätzt werden.

- Harthölzer: Eiche und Buche, die eine hohe Festigkeit und Haltbarkeit bieten.

Wichtige Faktoren bei der Holzauswahl:

- Feuchtigkeitsgehalt.

- Keine Mängel wie Risse und Astlöcher.

- Einhaltung der ISPM-15-Standards für den internationalen Transport.

-

Holzzuschnitt

Stämme werden in Bretter der gewünschten Größe geschnitten. Dies geschieht mit Bandsägen und Kreissägen, die hohe Präzision bieten. -

Holztrocknung

Um Verformungen und Pilzwachstum zu vermeiden, wird das Holz in speziellen Kammern auf einen Feuchtigkeitsgehalt von 18–22 % getrocknet. Dies ist eine obligatorische Phase zur Einhaltung internationaler Standards. -

Palettenmontage

Die Montage erfolgt automatisch auf Produktionslinien. Der Prozess umfasst:

- Nagelmaschinen, die eine feste Verbindung der Komponenten gewährleisten.

- Robotersysteme zum Verlegen und Befestigen der Bretter.

-

Hitzebehandlung (Heat Treatment, HT)

Dieser Schritt ist erforderlich, um Schädlinge und Pilze zu beseitigen. Das Holz wird auf eine Temperatur von 56 °C für mindestens 30 Minuten erhitzt. -

Qualitätskontrolle und Kennzeichnung

Jede Palette wird geprüft, um die Einhaltung der Standards sicherzustellen. Fertige Produkte werden gekennzeichnet, um ihre Qualität und die Einhaltung der Anforderungen zu bestätigen.

Wichtige Produktionstechnologien

Die moderne Produktion von Holzpaletten ist ohne den Einsatz hochmoderner Lösungen nicht möglich:

-

Roboter-Montagelinien

Innovative Robotersysteme beschleunigen den Montageprozess, minimieren menschliche Fehler und erhöhen die Präzision. -

Automatisierte Trockenkammern

Diese Systeme sorgen für eine gleichmäßige Feuchtigkeitsentfernung aus dem Holz und gewährleisten eine gleichbleibende Produktqualität. -

Qualitätskontrollsysteme

Scanner und Sensoren messen die Abmessungen, den Feuchtigkeitsgehalt und die Festigkeit der Paletten und verhindern Mängel. -

Produktionsmanagement-Software

Integrierte Managementsysteme überwachen jede Produktionsphase, optimieren den Materialverbrauch und steigern die Effizienz.

Holzverarbeitungsmethoden

Zur Herstellung hochwertiger Paletten werden verschiedene Holzverarbeitungsmethoden eingesetzt:

-

Mechanische Verarbeitung

Dazu gehören Schneiden, Hobeln und Schleifen der Bretter, um die erforderlichen Abmessungen und glatte Oberflächen zu erzielen. -

Chemische Behandlung

Um die Widerstandsfähigkeit gegen Feuchtigkeit und Schädlinge zu erhöhen, kann das Holz mit speziellen Chemikalien behandelt werden. -

Imprägnierung

Dieser Prozess umfasst das Tränken des Holzes mit Schutzmitteln, die Fäulnis verhindern und die Lebensdauer verlängern. -

Reparatur und Wiederherstellung

Beschädigte Paletten werden durch den Austausch einzelner Elemente repariert. Dies reduziert Kosten und minimiert Abfälle.

Standards und deren Bedeutung

-

EPAL (European Pallet Association)

Europäische EPAL-Standards gewährleisten einheitliche Abmessungen, Festigkeit und Qualität. Sie eignen sich ideal für automatisierte Lagersysteme und internationalen Transport. -

ISPM-15

Dieser internationale Standard regelt die Holzbehandlung für den Export und verhindert die Verbreitung von Schädlingen. -

GMA (General Manufacturing Association)

Ein Standard für Nordamerika, mit Palettenmaßen von 1200 x 1000 mm. -

Nationale Standards

Einige Länder haben eigene Anforderungen an Paletten, die bei der Produktionsplanung berücksichtigt werden sollten.

Umweltaspekte der Produktion

Die Produktion von Holzpaletten kann nachhaltig und umweltfreundlich gestaltet werden:

-

Verwendung von Abfallmaterialien

Holzabfälle werden zu Spänen recycelt, aus denen neue Produkte oder Brennstoffpellets hergestellt werden. -

Wiederverwendung

Beschädigte Paletten werden wiederhergestellt, was die Nachfrage nach Rohstoffen reduziert. -

Niedriger CO₂-Fußabdruck

Im Vergleich zu Kunststoffpaletten hinterlassen Holzpaletten einen minimalen ökologischen Fußabdruck. -

FSC-Zertifizierung

Die Verwendung von FSC-zertifiziertem Holz stellt sicher, dass Rohstoffe aus verantwortungsvoll bewirtschafteten Wäldern stammen.

Innovationen in der Produktion

Moderne Hersteller setzen innovative Ansätze um, um die Produktion zu verbessern und sich an die sich ändernden Marktanforderungen anzupassen:

-

Intelligente Paletten

Mit Sensoren ausgestattete Paletten können ihren Standort und Zustand in Echtzeit verfolgen. -

Gewichtsreduktion

Die Entwicklung leichter Konstruktionen senkt die Transportkosten und verbessert die Effizienz. -

Modulare Paletten

Diese Paletten können an verschiedene Ladungsgrößen angepasst werden und sind daher vielseitiger einsetzbar. -

3D-Druck von Komponenten

In einigen Fällen können einzelne Palettenkomponenten mit 3D-Druck hergestellt werden, was den Prozess beschleunigt und die Kosten senkt.

Die Zukunft von Holzpaletten

In den kommenden Jahren wird sich die Produktion von Holzpaletten in mehreren Bereichen weiterentwickeln:

- Zunehmende Automatisierung und Robotik.

- Erhöhte Nachhaltigkeit der Materialien.

- Integration von IoT-Technologien in Paletten.

- Entwicklung neuer Standards für Hybridmaterialien (Holz und Kunststoff).

Fazit

Die Produktion von Holzpaletten ist ein hochmoderner und facettenreicher Prozess, der die Verwendung hochwertiger Rohstoffe, moderner Technologien und die Einhaltung strenger Standards vereint. Diese Produkte spielen eine entscheidende Rolle in der Logistik, indem sie eine wirtschaftliche, zuverlässige und nachhaltige Lösung für den Transport und die Lagerung von Gütern bieten.

Wenn Sie mehr über die Produktionstechnologie erfahren oder zuverlässige Holzpaletten suchen möchten, kontaktieren Sie uns. Wir helfen Ihnen dabei, die optimale Lösung für Ihr Unternehmen zu finden!